Semiconductor

Marking

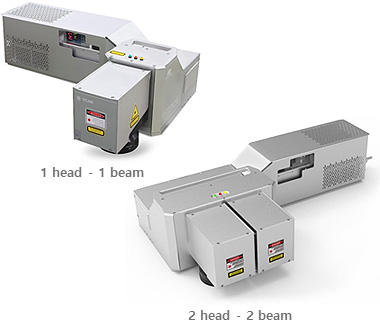

Strip marker

(2 beam/4 beam marker)

- The 4-beam strip marker for semiconductor can support both slot and stack magazine for loading & unloading. The strip handling is divided into two types, shuttle and rail types and the loading/unloading methods such as 1 in 1 out, 2 in 2 out and etc. can be configured in accordance with customers' request.

| Shuttle type | Placing the strips on the shuttle for handling |

|---|---|

| Rail type | Moving the strips along the rail with indexing motors; faster transfer |

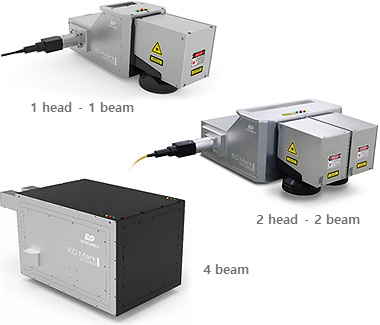

Tray marker

(2 beam/4 beam marker)

- Tray marker for semiconductor can be manufactured as compact ‘U’ type and conventional "I" type.

| U type | Small footprint, easy to operate with short tray movement distance |

|---|---|

| I type | Available for the large-sized lasers |

Wafer back side marker

CSM3200/3300

- CSM series is the wafer level chip scale marker for semiconductor and can mark on wafer backside without any chip damages.

The equipment has an automated calibration system to compensate scanner accuracy and an automated marking inspection system to check the marking results.

| Combo type | Applicable for both FFC and bare wafer in single equipment. |

|---|

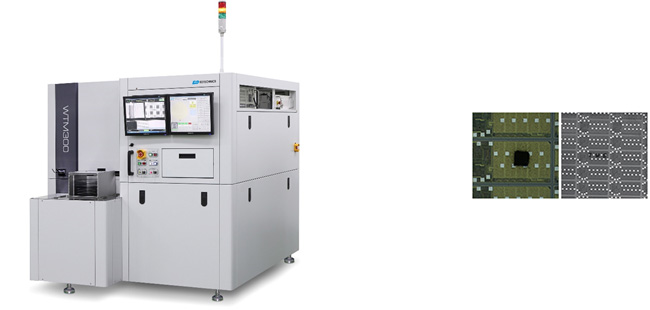

Wafer top side marker

WTM200/300

- WTM series is for marking reference die, bad die and wafer ID on a wafer.

It provides wafer top side marking solution with high-speed processing and a user-friendly program

Wafer ID marker

WM080/012

- WM series is wafer ID marking system used in cleanroom.

It has high-degree stability and high-speed processing.

It also has OCR edit function which the user can edit by themselves.

Grooving & Dicing

LMC3200G/LMC3200D

- Grooving

LMC3200G removes the low-k material and metal pattern layers on the wafer sawlane.

It not only improves the yield rate but also reduces wafer chipping during

the blade dicing processing. - Dicing

LMC3200D is a dicing system for thin wafer of less than 200㎛.

It is better than mechanical blade dicing system in terms of COO, sicne it doesn’t need to replace

blade and the lifetime of laser parts is long and semipermanent.

The non-contact process can dramatically reduce the problem of chipping and enable high-speed

processing.

Cutting

PKG cutting

BMC254

- It is a package cutting equipment for substrates.

The higher accuracy can be achieve by using alignment vision and automatic scanner compensation feature.

It provides good quality performance and high productivity with flying processing method.

Drilling

PoP drilling

BMC204P

- BMC204P is a package drilling equipment for the strip and wafer types of POP. Its automatic inspection and scanner compensation feature make the process highly accurate.

It adopts flying processing method to increase productivity.